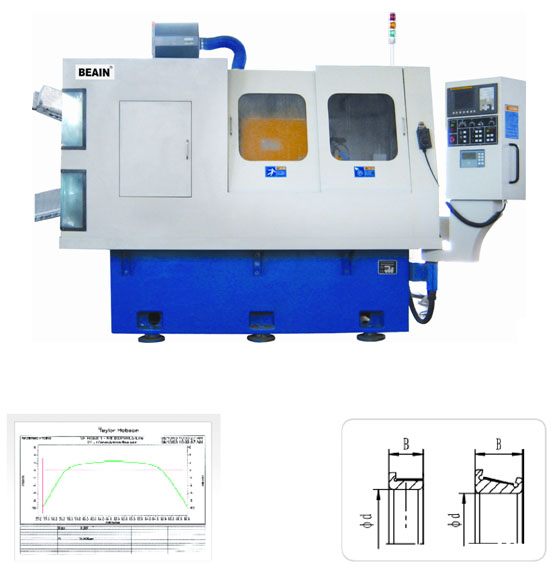

CNC OUTER TRACK (CROWNED) GRINDER FOR ROLLER BEARINGS

【Main Applications】

Outer track grinding for single & double row cylindrical and tapered roller bearings

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (3-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck.

3. Workhead slide, wheelhead slide and dresser slide are all equipped with servo motors and ball-screws.

4. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

5. Wheel dresser is of pen type single-point diamond pen which adopts interpolated method in wheel dressing so as to realize crowned track grinding. The crowning shape can be arc or double logarithm type, depending on customers' demand.

6. Adopting plunge-cut grinding method, powerful and high rigid spindle, the constant linear grinding speed can reach up to 60 m/s.

7. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

8. Equipped with flushing system for easy cleaning and maintenance of the machine.

9. Definite distance measurement and NC gauge measurement in process are optional.

10. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

11. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specification】

|

Machine model |

Workpiece OD

mm |

Workpiece width

mm |

Swivel angle of workhead |

Processing accuracy |

Straightness of workpiece |

Total power kW |

Weight kg |

|

3MZ2310CNC |

30-100 |

14-40 |

0-30° |

P4,P5 |

Convex and curve shape can be adjusted according to customer's request |

18 |

3000 |

|

3MZ2316CNC |

60-160 |

15-55 |

0-30° |

P4,P5 |

22 |

4800 |

|

3MZ2320CNC |

80-200 |

20-70 |

0-30° |

P4,P5 |

25 |

5000 |

|

3MZ2325CNC |

100-250 |

25-80 |

0-30° |

P4,P5 |

28 |

5200 |

|

3MZ2335CNC |

190-350 |

40-220 |

0-30° |

P4,P5 |

50 |

7500 |

|

3MB2345CNC |

180-450 |

30-150 |

0-30° |

P4,P5 |

35 |

6000 |

|

3MB2345ACNC |

180-450 |

30-300 |

0-30° |

P4,P5 |

35 |

7000 |

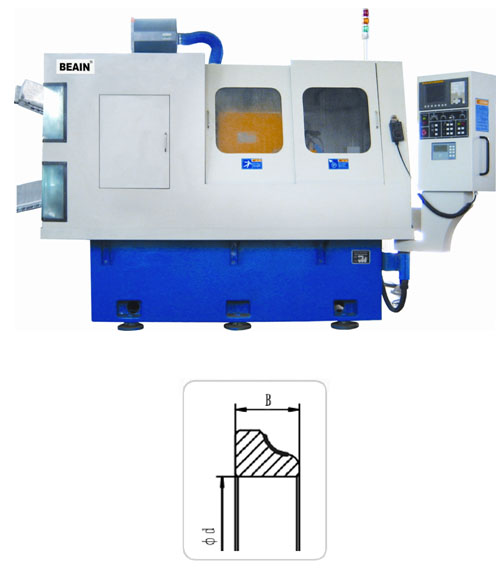

CNC INNER TRACK (CROWNED) GRINDER FOR ROLLER BEARINGS

【Main Applications】

Inner track grinding for single & double row cylindrical and tapered roller bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (3-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Centreless grinding machine arrangement, plunge-cut grinding technology, fixed wheel frame with workhead feeding and dresser compensation.

3. Work spindle drive is speed-variable with F.C.. Workpiece is gripped with an electromagnetic chuck while the track is ground with floating supports on it.

4. The wheel spindle is supported with a hydro-hybrid bearing and the wheel is balanced with an in-process balancer.

5. Feeding system is equipped with a high power and big-torque servo motor, and the feeding and dressing compensation is realized with elastic coupling joints and ball screws (THK make).

6. Wheel dresser driven by servo motor is of pen-type single-point diamond which adopts interpolated method in wheel dressing so as to realize the crowned track grinding. The crowning shape can be arc or double logarithm type, depending on customer’s demand.

7. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

8. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

9. Equipped with flushing system for easy cleaning and maintenance of the machine.

10. Definite distance measurement and NC gauge measurement in process are optional.

11. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

12. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine Model |

Workpiece OD

mm |

Workpiece width

mm |

Swivel angle of workhead |

Processing accuracy |

Straigthness of workpiece |

Total power

kW |

Weight

kg |

|

3MZ216CNC |

17-60 |

12-40 |

0-30° |

P4,P5

|

Convex and curve shape can be adjusted according to customer’s request |

15 |

3500 |

|

3MZ2110CNC |

50-120 |

20-70 |

0-30° |

18.5 |

5500 |

|

3MZ2116CNC |

80-160 |

30-80 |

0-30° |

22 |

5800 |

|

3MZ2120CNC |

90-200 |

40-110 |

0-30° |

25 |

6500 |

|

3MB2130CNC |

150-300 |

30-150 |

0-30° |

27 |

7500 |

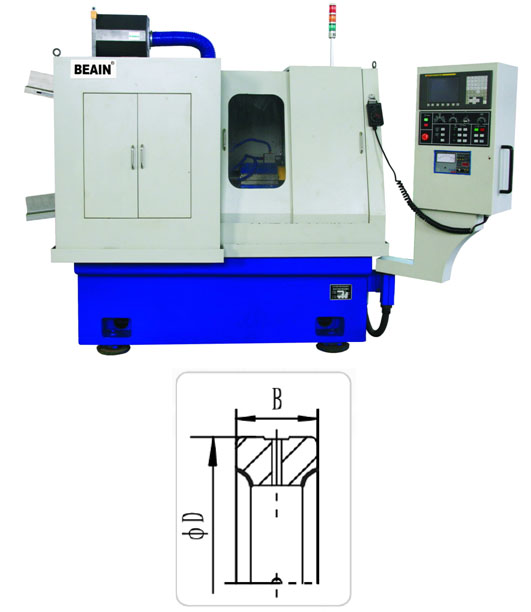

CNC OUTER RING FLANGE GRINDER

FOR CYLINDRICAL ROLLER BEARINGS

【Main Applications】

Outer ring flange grinding for single/double row cylindrical roller bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck.

3.Workhead slide and wheelhead slide are driven by servo motors through ball screws (THK make).

4. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

5. Grinding wheel is dressed automatically by two-points diamond pen-type dresser.

6. Using lambdoid profiled wheel which widens the grinding area similarly to O.D. grinding method. The cooling effect is excellent.

7. Two to four flanges can be ground in sequence at one positioning.

8. Oscillation of the workpieces can be set to improve the roughness of flanges.

9. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

10. Equipped with flushing system for easy cleaning and maintenance of the machine.

11. Definite distance measurement and NC gauge measurement in process are optional.

12. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

13. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine Model |

Workpiece OD

mm |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ2610CNC |

30-100 |

14-40 |

P4,P5

|

15 |

3000 |

|

3MZ2616CNC |

60-160 |

15-55 |

19 |

3500 |

|

3MZ2620CNC |

80-200 |

20-70 |

20 |

3500 |

|

3MZ2625CNC |

100-250 |

25-80 |

22 |

4000 |

|

3MZ2635CNC |

190-350 |

40-120 |

25 |

5000 |

|

3MB2645CNC |

180-450 |

30-150 |

30 |

5500 |

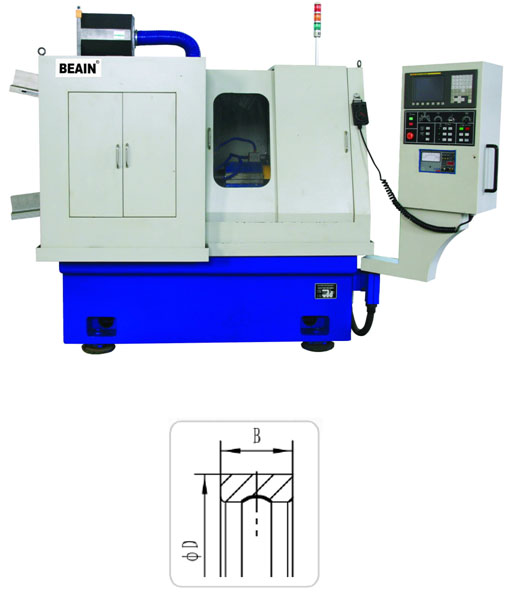

CNC BORE GRINDER FOR BALL AND ROLLER BEARINGS

【Main Applications】

Bore grinding for ball/roller bearings or outer track grinding of roller bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (1 or 2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive and oscillation slide motors are speed-variable with F.C.

3. Workhead slide is driven by servo motor.

4. Wheelhead slide is driven by either servo motors or hydraulic cylinder. To-and- fro movement of the grinding wheel is realized by a servo motor or eccentric wheel driven by a speed-variable motor.

5. Grinding wheel is dressed automatically by single-point diamond pen-type dresser.

6. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

7. The machine is equipped with active in-process measuring system.

8. Wheelhead uses high frequency spindle with high speed and stiffness. F.C. can be user-customerized.

9. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

10. Equipped with flushing system, the machine is easy to keep clean.

11. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

12. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine model |

Workpiece ID

mm |

Workpiece width

mm |

Swivel angle of workhead |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ206CNC |

15-60 |

12-40 |

0-30° |

P4,P5 |

15 |

3000 |

|

3MZ2010NC |

50-120 |

20-70 |

0-30° |

19 |

4500 |

|

3MZ2016CNC |

80-160 |

30-80 |

0-30° |

20 |

4500 |

|

3MZ2020CNC |

90-200 |

40-110 |

0-30° |

30 |

5000 |

|

3MB2030CNC |

150-300 |

30-150 |

0-30° |

30 |

5500 |

CNC GRINDER FOR OUTER RING SEALING SURFACE AND RACEWAY OF AUTOMOTIVE WHEEL HUB BEARING UNITS

【Main Applications】

Outer raceway and sealing surface grinding for wheel hub bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2 or 3-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck.

3. Feeding systems of wheelhead and workhead adopt high precision and high stiffness cross roller guideway to guarantee the high rigidity and long service time. The workhead can be micro-adjusted in bi-direction.

4. Feeding systems of both workhead and wheelhead are equipped with high power and big torque servo motor, flexible coupling joints and precision ball screw (THK make).

5. The dresser slide is driven by servo motor through ball screw (THK make).

6. Grinding wheel is dressed automatically by diamond roller-type dresser.

7. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

8. Equipped with flushing system, the machine is easy to keep clean.

9. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

10. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

11. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine model |

Workpiece OD (mm) |

Workpiec width (mm) |

Total power (kW) |

Weight (kg) |

|

3MZ1412GLCNC |

50-120 |

20-50 |

20 |

4000 |

|

3MZ1420GLCNC |

60-160 |

20-80 |

30 |

5000 |

CNC GRINDER FOR INNER RING SEALING SURFACE, RACEWAY AND SAMLLER ENDFACE OF AUTOMOTIVE WHEEL HUB BEARINGS UNITS

【Main Applications】

Inner raceway, sealing surface and smaller endface grinding for wheel hub bearings (HBU1.2.3).

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2 or 3-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Centreless grinding machine arrangement, plunge-cut grinding technology, fixed wheel frame with workhead feeding and dresser compensation and active in-process measuring system.

3. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck while the raceway is ground with floating supports on it.

4. Workhead swivel angle range is 0-45°adjustable so as to grind the raceway with different contact angles.

5. Hydro-hybrid wheel spindle unit equipped with in-process wheel balancer.

6. Feeding system and dressing system are all equipped with high power and big torque AC servo motors, flexible coupling joints and precision ball screws (THK make).

7. Workhead slide and dressing slide adopt high precision and high stiffness cross roller guideway (THK make).

8. Grinding wheel is dressed automatically by a diamond roller-type dresser.

9. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

10. Equipped with flushing system, the machine is easy to keep clean.

11. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

12. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

13. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine modle |

Workpiece OD (mm) |

Workpiece width (mm) |

Total power (kW) |

Weight (kg) |

|

3MZ136GLCNC |

40-80 |

20-50 |

18 |

6000 |

|

3MZ1310GLCNC |

80-180 |

50-90 |

20 |

7000 |

CNC SHAFT-RING RACEWAY GRINDER FOR ANGULAR CONTACT BIDIRECTIONAL THRUST BALL BEARINGS

【Main Applications】

Raceway grinding for the shaft-ring of bidirectional angular contact thrust ball bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Centreless grinding machine arrangement, plunge-cut grinding technology, fixed wheel frame with workhead feeding and dresser compensation.

3. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck while the raceway is ground with floating supports on it.

4. Workhead swivel angle range is 0-60°adjustable so as to grind the raceway with different contact angles.

5. Hydro-hybrid wheel spindle unit equipped with in-process wheel balancer.

6. Feeding system and dressing system are all equipped with high power and big torque AC servo motors.

7. Workhead slide and dressing slide adopt high precision and high stiffness cross roller guideway (THK make).

8. Grinding wheel is dressed automatically by radius diamond dresser for wheel OD and flat diamond dresser for wheel side.

9. Single-arm elected automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

10. Equipped with flushing system, the machine is easy to keep clean.

11. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

12. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

13. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine model |

Workpiece ID

mm |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ1310/1CNC |

70-120 |

12-25 |

P4、P5 |

18.5 |

5500 |

|

3MZ1320/1CNC |

80-200 |

25-45 |

22 |

6500 |

CNC HOUSING-RING RACEWAY GRINDER FOR ANGULAR CONTACT BIDIRECTIONAL THRUST BALL BEARINGS

【Main Applications】

Raceway grinding for the housing-ring of bidirectional angular contact thrust ball bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, “man-machine conversation” interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Centreless grinding machine arrangement, plunge-cut grinding technology, fixed wheel frame with workhead feeding and dresser compensation.

3. Work spindle drive is speed-variable with F.C. and workpiece is gripped by electromagnetic centreless chuck while the raceway is ground with floating supports on it.

4. Workhead swivel angle range is 0-60°adjustable so as to grind the raceway with different contact angles.

5. Hydro-hybrid wheel spindle unit equipped with in-process wheel balancer.

6. Feeding system and dressing system are all equipped with high power and big torque AC servo motors.

7. Workhead slide and dressing slide adopt high precision and high stiffness cross roller guideway (THK make).

8. Grinding wheel is dressed automatically by radius diamond dresser for wheel OD and flat diamond dresser for wheel side.

9. Single-arm elected automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

10. Equipped with flushing system, the machine is easy to keep clean.

11. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

12. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

13. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine modle |

Workpiece OD

mm |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ1420/1CNC |

80-200 |

14-45 |

P4、P5 |

20 |

4000 |

|

3MZ1445/1CNC |

180-450 |

30-80 |

30 |

5500 |

CNC RACEWAY GRINDER FOR THRUST BALL BEARINGS

【Main Applications】

Raceway grinding for thrust ball bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck.

3. Using plunge-cut grinding process, worked slide and wheelhead slide are driven by servo motors through ball screws. The guideway is of cross roller type (THK make).

4. High frequency motorized wheel spindle.

5. Grinding wheel is dressed automatically by radius diamond dresser.

6. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

7. Equipped with flushing system, the machine is easy to keep clean.

8. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

9. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

10. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine model |

Workpiece OD

mm |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ1012CNC |

40-120 |

6-15 |

P4、P5 |

18 |

4000 |

|

3MZ1020CNC |

80-200 |

10-50 |

20 |

4500 |

|

3MB1045CNC |

150-450 |

30-80 |

30 |

5500 |

CNC BALL BEARING OUTER GROOVE GRINDER

【Main Applications】

Outer raceway grinding for deep-groove ball bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck.

3. Using plunge-cut grinding process, worked slide and wheelhead slide are driven by servo motors.

4. With a swing cylinder, the wheel dresser is characterized as stable swing motion, good rigidity and high accuracy.

5. The dresser slide is driven by servo motor through ball screws which minimizes groove position error.

6. Plunge-cut grinding at speed up to 60 m/s. Wheelhead is driven with high-speed, high-rigidity and high-power spindle.

7. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

8. Equipped with flushing system, the machine is easy to keep clean.

9. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

10. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

11. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine model |

Workpiece OD

mm |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ147CNC |

30-72 |

10-20 |

P4、P5 |

15 |

3000 |

|

3MZ1410CNC |

40-100 |

12-30 |

17 |

3000 |

|

3MZ1420CNC |

80-200 |

20-50 |

20 |

4500 |

|

3MZ1425CNC |

100-250 |

30-60 |

25 |

5000 |

|

3MB1445CNC |

150-450 |

30-120 |

30 |

5500 |

CNC BALL BEARING INNER GROOVE GRINDER

【Main Applications】

Inner raceway grinding for deep-groove ball bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Centreless grinding machine layout, plunge-cut grinding technology, fixed wheel frame with workhead feeding and dresser compensation.

3. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck while the raceway is ground with floating supports on it.

4. Hydro-hybrid wheel spindle unit equipped with in-process wheel balancer.

5. Feeding system and dressing system are all equipped with high power and big torque AC servo motors, flexible coupling joints and precision ball screws (THK make).

6. Workhead slide and dresser slide are supported with high rigid cross roller guideway to ensure high rigidity and long service life.

7. With upper and lower support and a swing cylinder, the dresser is characterized as good rigidity and high precision groove profile.

8. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

9. Equipped with flushing system, the machine is easy to keep clean.

10. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

11. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

12. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.v

【Main Specification】

|

Machine model |

Workpiece ID

mm |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ136CNC |

15-60 |

10-40 |

P4、P5 |

15 |

3000 |

|

3MZ1310CNC |

50-100 |

20-60 |

18.5 |

5500 |

|

3MZ1316CNC |

80-160 |

20-80 |

18.5 |

5800 |

|

3MZ1320CNC |

100-200 |

40-100 |

25 |

6500 |

|

3MB1330CNC |

150-300 |

40-120 |

30 |

7000 |

CNC TO-AND-FRO DOUBLE-FACE GRINDER

【Main Applications】

Outer ring endface grinding for railway bearings or larger sized bearings (diameter range 150 to 380 mm).

【Main Features】

1. Implemented with Japan's FANUC all digital servo system with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. The wheelhead slide is driven by AC servo motor+ball screw (THK) and supported by THK linear ball guideway.

3. To-and-fro grinding manner ensures the stable dimension and high accuracy of the workpieces processed. The workhead is driven by servo motor+ball screw and the workhead slide is supported by THK ball linear guideway.

4. The machine is equipped with a 3-axis servo system and a mechanical backlash elimination device.

5. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

6. Wheel spindle is supported with imported high-speed bearings.

7. Large-capacity coolant tank with fine coolant filter device and high pressure pump at high flow rate.

8. Two wheels are dressed simultaneously with a double-point diamond pen.

9. Equipped with flushing system, the machine is easy to keep clean.

10. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

【Main Specifications】

|

Machine model |

Workpiece OD |

Workpiece width

mm |

Processing accuracy |

Total power

kW |

Weight

kg |

|

Parellelness deviation |

Plane deviation |

Dimension scattering |

|

3MB7675WCNC |

150-400 |

40-220 |

<0.005 |

≤0.004 |

0.020 |

50 |

12000 |

CNC INNER RING FLANGE GRINDER FOR ROLLER BEARINGS

【Main Applications】

Inner ring flange grinding for single/double row cylindrical roller bearings and single row tapered roller bearings.

【Main Features】

1. Implemented with Japan's FANUC all digital servo system (2-axis) with color display, "man-machine conversation" interface, manual pulse generator and self-diagnostics, the control system is stable, reliable, easy to maintain and convenient in adjustment.

2. Work spindle drive is speed-variable with F.C. and workpiece is gripped with an electromagnetic centreless chuck.

3. Workhead slide and wheelhead slide are driven by servo motors through ball screws (THK make).

4. Automatic loading and unloading manipulator is stable, reliable, versatile, easy to adjust and free from dent mark on workpieces.

5. Grinding wheel is dressed automatically by single-point diamond pen-type dresser.

6. Plunge-cut grinding with straight generatrix, belt driven spindle or high rigid spindle.

7. Maximum linear cutting speed of the wheel is up to 60 m/s which is automatically adjusted through F.C. during the wheel worn-out so that the constant linear speed of wheel is adjustable.

8. Oscillation of the workpieces can be set to improve the roughness of flanges and keep them from being burned.

9. The machine may be equipped with active in-process measuring system (optional). Two kinds of grinding manners are available, definite distance manner and auto gauge manner.

10. Centralized lubrication system provides timing, quantitative and duly lubrication of ball screws.

11. Equipped with flushing system for easy cleaning and maintenance of the machine.

12. High grade cast-iron machine body with double aging treatment assures the overall accuracy performance.

13. Painted and enclosed machine guard is nice looking and splash-proof and has a long service life.

【Main Specifications】

|

Machine model |

Workpiece OD

mm |

Workpiece width

mm |

Flange angle |

Processing accuracy |

Total power

kW |

Weight

kg |

|

3MZ226CNC |

15-60 |

12-40 |

0-30° |

P4,P5

|

10 kW |

3000 Kg |

|

3MZ2210CNC |

50-120 |

20-70 |

0-30° |

15 kW |

3800 Kg |

|

3MZ2216CNC |

80-160 |

30-80 |

0-30° |

18 kW |

4200 Kg |

|

3MZ2220CNC |

90-200 |

40-110 |

0-30° |

20 kW |

4500 Kg |

|

3MB2230CNC |

150-300 |

30-150 |

0-30° |

25 kW |

5000 Kg |